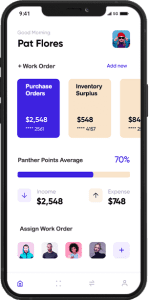

The Panther CMMS Maintenance Management Module mobile app offers a range of features to streamline maintenance processes:

- Up-to-date inventory of available spares with item code and location tracking

- Generate tickets for breakdown, preventive, and asset management

- Assign priority to tickets and provide root cause corrective and preventive actions

- Track maintenance tickets with current status (in progress, open, closed)

- Schedule and carry out maintenance more effectively

Maintenance management is one of the major pillars of any well-functioning organization and determines a company’s long term success. It is a regular and methodological process of keeping the assets up to date and in working condition. However, this task is not easy and requires careful attention to detail.

Poor maintenance of assets can cause instability, performance failure, or even complete breakdowns, which can result in significant financial losses. To address these challenges, Panther CMMS maintenance management software offers a solution. With our computerized maintenance management system, facility managers can efficiently keep track of each asset’s performance and maintenance.

Long-term success in maintenance management requires a strategic approach that focuses on optimizing assets, enhancing reliability, and maximizing efficiency over an extended period. Here are key factors to consider:

Asset Lifecycle Management: Implement a comprehensive asset lifecycle management strategy that encompasses the entire lifespan of assets, from acquisition to disposal. This involves planning for maintenance, repairs, upgrades, and eventual replacement to ensure assets remain operational and cost-effective throughout their lifecycle.

Preventive Maintenance Programs: Develop and maintain preventive maintenance programs to proactively address issues before they lead to downtime or costly repairs. Regular inspections, scheduled maintenance tasks, and predictive maintenance techniques help minimize unexpected breakdowns and extend asset lifespan.

Data-Driven Decision Making: Leverage data and analytics to inform maintenance decisions and optimize asset performance. Utilize tools such as computerized maintenance management systems (CMMS) to collect and analyze data on asset condition, maintenance history, and performance metrics, enabling more informed decision-making and resource allocation.

Reliability-Centered Maintenance (RCM): Implement reliability-centered maintenance practices to prioritize maintenance activities based on the criticality of assets and their potential impact on operations. RCM focuses resources on maintaining the reliability of critical assets while optimizing maintenance efforts for less critical ones.

Continuous Improvement: Foster a culture of continuous improvement within the maintenance management team. Encourage feedback, identify areas for enhancement, and implement process improvements to increase efficiency, reduce costs, and enhance overall performance over time.

Training and Skill Development: Invest in training and skill development for maintenance personnel to ensure they have the necessary knowledge and expertise to perform their roles effectively. Provide opportunities for ongoing education, certification, and cross-training to keep skills current and relevant.

Supplier and Vendor Management: Establish strong relationships with suppliers and vendors to ensure timely access to spare parts, equipment, and external services. Negotiate favorable contracts, monitor performance, and seek opportunities for collaboration to support maintenance activities and minimize downtime.

Safety and Compliance: Prioritize safety and compliance in maintenance operations to protect personnel, assets, and the environment. Ensure compliance with relevant regulations, provide comprehensive safety training, and implement procedures to mitigate risks associated with maintenance activities.

Sustainability Initiatives: Integrate sustainability initiatives into maintenance management practices to minimize environmental impact and reduce resource consumption. Explore opportunities for energy efficiency improvements, waste reduction, and sustainable procurement practices to support long-term sustainability goals.

Strategic Planning and Alignment: Align maintenance management goals and strategies with broader organizational objectives to ensure alignment and support for long-term success. Collaborate with other departments, such as operations, finance, and facilities, to develop integrated plans that prioritize maintenance efforts in support of overall business objectives.

By focusing on these key areas and adopting a proactive, data-driven approach to maintenance management, organizations can achieve long-term success by maximizing asset reliability, minimizing downtime, and optimizing maintenance operations.

Empowering Field Technicians

Our easy-to-use mobile app empowers field technicians by simplifying their day-to-day maintenance tasks. They can easily manage service tickets on the go, ensuring efficient and timely resolution of issues. The app also enables location or sitewide breakdown tracking, providing valuable insights for the decision-making process.

Effective Asset Maintenance

Maintenance management software plays a crucial role in ensuring timely maintenance for each asset. By using our software, managers can easily identify when an asset needs maintenance and schedule it accordingly. Assigning roles and responsibilities to maintenance personnel allows for immediate action, minimizing the risk of asset failure.

Our software emphasizes preventive maintenance, which helps in preventing unexpected breakdowns and extends the lifespan of assets. It also validates tickets, manages spare inventory, and facilitates planned preventive maintenance (PPM) activities. These features reduce the chances of asset failure and increase overall efficiency.

Vendor Data and Feedback

With our annual maintenance option, you can easily review and update vendor data and feedback. This feature also keeps track of contract expiration dates for each asset, ensuring timely renewals and uninterrupted service.

By utilizing the Panther CMMS Maintenance Management software, your organization can maintain its assets in a more efficient and controlled manner. Preventing asset failure, increasing efficiency, and extending asset lifespan are key factors in achieving long term success in today’s competitive business landscape.

Don’t miss out on the benefits of effective maintenance management. Try Panther CMMS Maintenance Management software and take control of your organization’s assets today.